Hardware features:

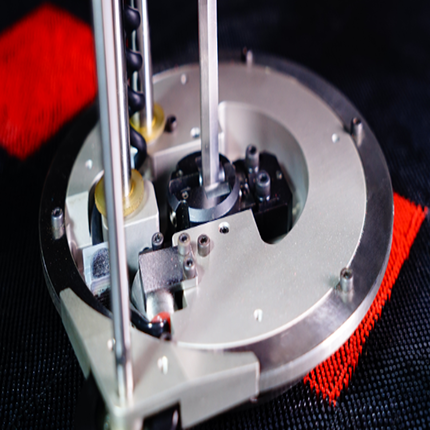

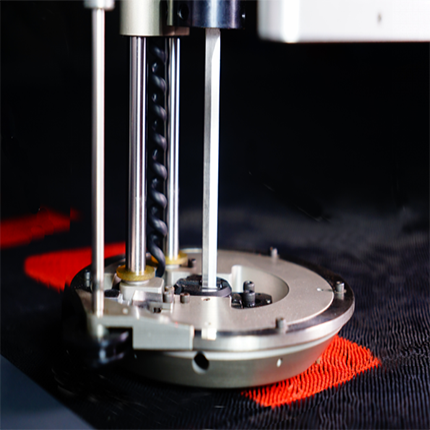

1. The main vibration of the cutting knife can reach up to 6000r/min, ensuring sufficient power of the equipment.

2. 15000r/min high-speed automatic grinding, and various specifications of abrasive belts are optional to ensure that the blade remains sharp and can easily deal with various fabrics.

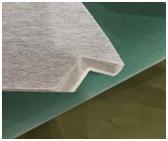

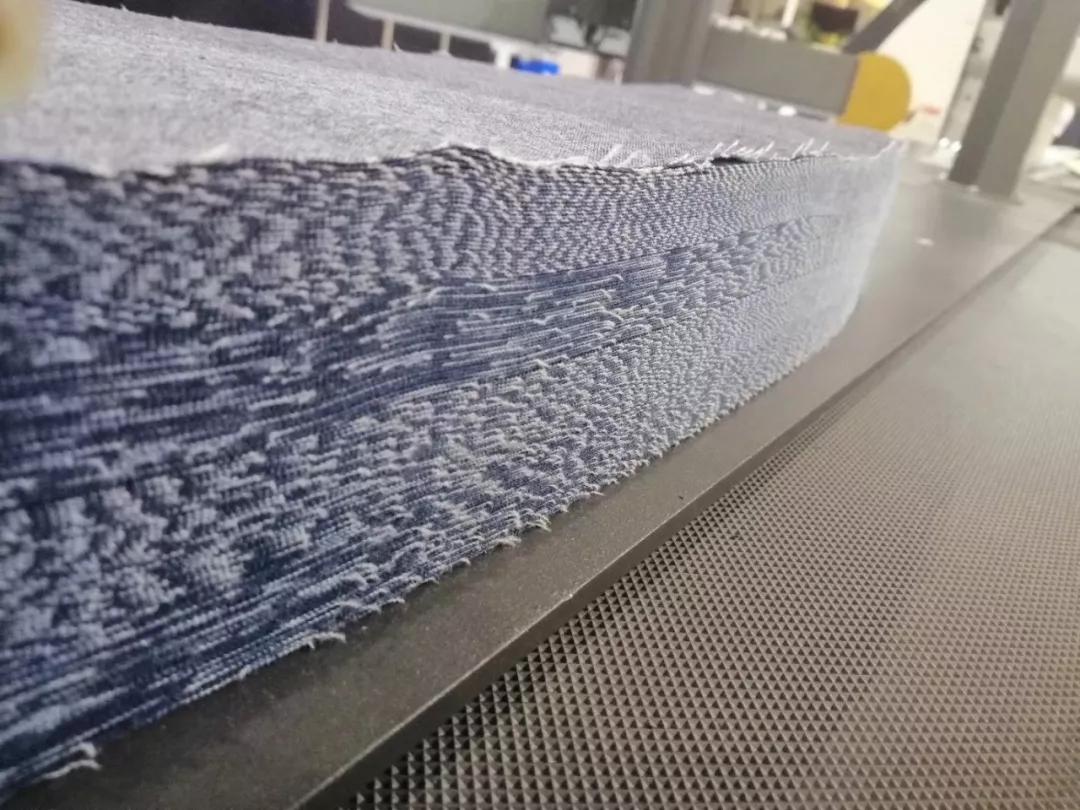

3. The world's advanced 4. The negative pressure in the cutting area can reach -22Kpa.

5. The drill needle adopts a digital heating system, which can easily penetrate various materials.

6. The gas pressure adjustment adopts a digital control system without manual adjustment.

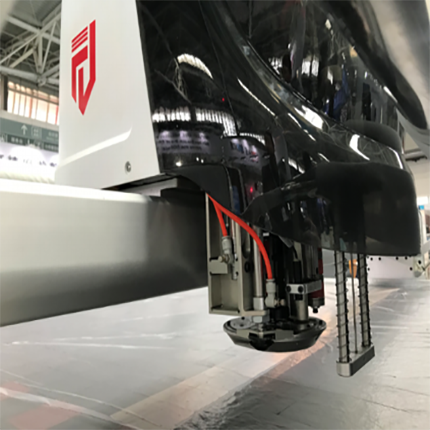

7. The beam of the equipment is equipped with a reliable collision quick reset device, which effectively protects the key parts and the personal safety of employees.

8. The key components are all German accessories, with high-end configuration, good stability and durability.

9. Ergonomics Design, equipped with intelligent operation terminal, friendly interface, easy to learn.

Software Features

1. The cutting system has remote diagnosis and remote assistance functions, and the after-sales service responds quickly.

2. The cutting path is memorized in real time, and the cutting can be automatically resumed after power failure.

3. It can monitor the wear and tear of consumable parts in real time, and has an automatic reminder function.

4. It can monitor the voltage and current status of core parts to prevent equipment failure.

5. It has the function of production statistics.

6. Multi-task cutting: while cutting, the next layout map can be preset.

7. Integrated cutting: it can integrate multiple.

8. Adjacent pieces and selvedge pieces, the cutting speed can be adjusted intelligently.

9.The cutting area can be set arbitrarily.

Call: +8801813564620 +8801684339325 +8801731402133

Share:

Hardware features:

1. The main vibration of the cutting knife can reach up to 6000r/min, ensuring sufficient power of the equipment.

2. 15000r/min high-speed automatic grinding, and various specifications of abrasive belts are optional to ensure that the blade remains sharp and can easily deal with various fabrics.

3. The world's advanced 4. The negative pressure in the cutting area can reach -22Kpa.

5. The drill needle adopts a digital heating system, which can easily penetrate various materials.

6. The gas pressure adjustment adopts a digital control system without manual adjustment.

7. The beam of the equipment is equipped with a reliable collision quick reset device, which effectively protects the key parts and the personal safety of employees.

8. The key components are all German accessories, with high-end configuration, good stability and durability.

9. Ergonomics Design, equipped with intelligent operation terminal, friendly interface, easy to learn.

Software Features

1. The cutting system has remote diagnosis and remote assistance functions, and the after-sales service responds quickly.

2. The cutting path is memorized in real time, and the cutting can be automatically resumed after power failure.

3. It can monitor the wear and tear of consumable parts in real time, and has an automatic reminder function.

4. It can monitor the voltage and current status of core parts to prevent equipment failure.

5. It has the function of production statistics.

6. Multi-task cutting: while cutting, the next layout map can be preset.

7. Integrated cutting: it can integrate multiple.

8. Adjacent pieces and selvedge pieces, the cutting speed can be adjusted intelligently.

9.The cutting area can be set arbitrarily.

|

Product number |

FA-K50 |

FA-K80 |

FA-P60 |

FA-P90 |

|

Cutting height (after suction compression) mm |

50 |

80 |

60 |

90 |

|

Effective cropping area (L*W) mm |

1800x1800 (W: 2200) |

1800x1800 (W: 2200) |

1800x1800 (W: 2200) |

1800x1800 (W: 2200) |

|

Cutting knife specification mm |

2X7 |

2.4X8.5 |

2X7 |

2.4X8.5 |

|

Cutting speed (Max.) m/min |

50 |

50 |

80 |

80 |

|

Maximum acceleration m/s2 |

5 |

5 |

8 |

8 |

|

Vibration frequency (rpm) r/min |

3600 |

3600 |

6000 |

6000 |

|

Average power consumption kw |

10 |

10 |

12 |

12 |

|

removable device |

Optional |

Optional |

Optional |

Optional |

|

single drill |

Optional |

Optional |

Optional |

Optional |

|

Cutting knife cooling system |

Optional |

Optional |

Optional |

Optional |

|

Maximum Vacuum Negative Pressure |

-22Kpa |

|||

|

Equipment (LxW) mm |

4927X2230(2630) |

|||

|

Mechanical weight kg |

3800-4200 |

|||

|

Cutter offset automatic correction system |

Standard |

Standard |

Standard |

Standard |

|

Table height mm |

800-900 |

|||

|

VoltageV/Hz |

3P/N/PE, AC380/50 |

|||

|

power kw |

28 |

30 |

||

|

Gas flow unit NL/min |

160 |

|||

|

Compressed air-air pressure mpa |

0.7Mpa |

|||

|

Noise level dB |

<73 |

|||

|

CAD compatible |

Cutfile, ISO6983, RS274D, DXF, PLA, PLX, etc. |

|||

|

operating system |

WINDOWS |

|||